Making a Tablet Pill Mix - Bulk Density

Before put your powder mix into your powder V-mixer, we need to figure out the bulk density of the pill powder mix. A small change in powders can make a dramatic change your tablets. Making it important to measure the characteristics powders and granules during production. Also, bulk density should be checked from time to time as ingredients can change can be affected by things, such as, humidity. If left unchecked, the incorrect fourth may be applied which could lead to capping and lamination.

Before doing this, ensure your tablet mix is ready with your active and excipients and will flow nicely though your press. This step it to work out the size of tooling that is needed to determine the tablet size and what you are looking for.

To perform this test, we’ll take a 1 liter cylinder. This can be done with smaller cylinders or jugs, but it won’t be as accurate places in there onto the scales. The more precise the scales the better.

Now, tear the scales, have fill the cylinder up to the 1 liter mark with your mix.

Once it reaches the 1 liter mark, DON’T have the powder down as we want to be using what is called a loose bulk density.

As an example, if we shake our cylinder, we’ll see the powder compacted. This is known as your tamped bulk density, which were not interested in next record the weight of the 1 liter of powder. To calculate loose bulk density, take the weight of the full cylinder. In our example, is 597 grams, now devide it by the 1,000mL in the cylinder, which give us 0.597g/mL or cm³

597g ÷ 1000mL = 0.597 g/mL (or 0.597 g/cm³)

This can be used to calculate the weight of a tablet depending on the size of the die.

As an additional example, this is 597g of a different product. As you can see, it shows the major difference between products, this powder will be able to make a tablet twice as heavy with the same amount of powder as compared to the last one.

Now, we gonna calculate the maximum weight we can fill into our current die.

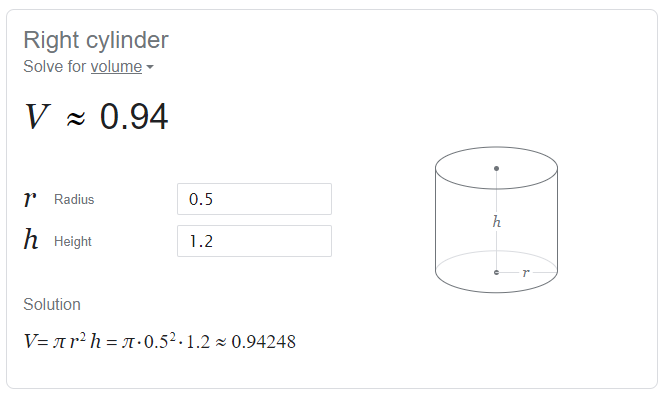

In this example, our die is 12mm fill depth. There’s a best practice to convert to cm (centimeters), so in this case, 1.2cm. Our die is a standard circle shape with a 10mm or 1cm die bore diameter.

From this, we need to calculate the total volume of our die bore, and find out the cubic cm inside. The maths to measure this is:

V = πr² x h

(r = radius, h = height, V = volume, π = 3.14159)

Google volume math tool.

So, 0.94cm³ is our maximum space in our die.

Now, we take our bulk density from earlier and time either by our maximum die space.

Bulk density: 597mg per cm³

Die bore size: 0.94cm³

597mg/cm³ x 0.94cm³ = 561.18mg

So, 561.18mg is our maximum for a die with a fill depth of 12mm and 10mm die bore. However, we could recommend to give some extra space, so we’d say 510mg would be the maximum before you consider a bigger die.

Hope it helps.

This is a 5-minute video about how to make to make tablet mix.