Step 1. Figuring out the recipe

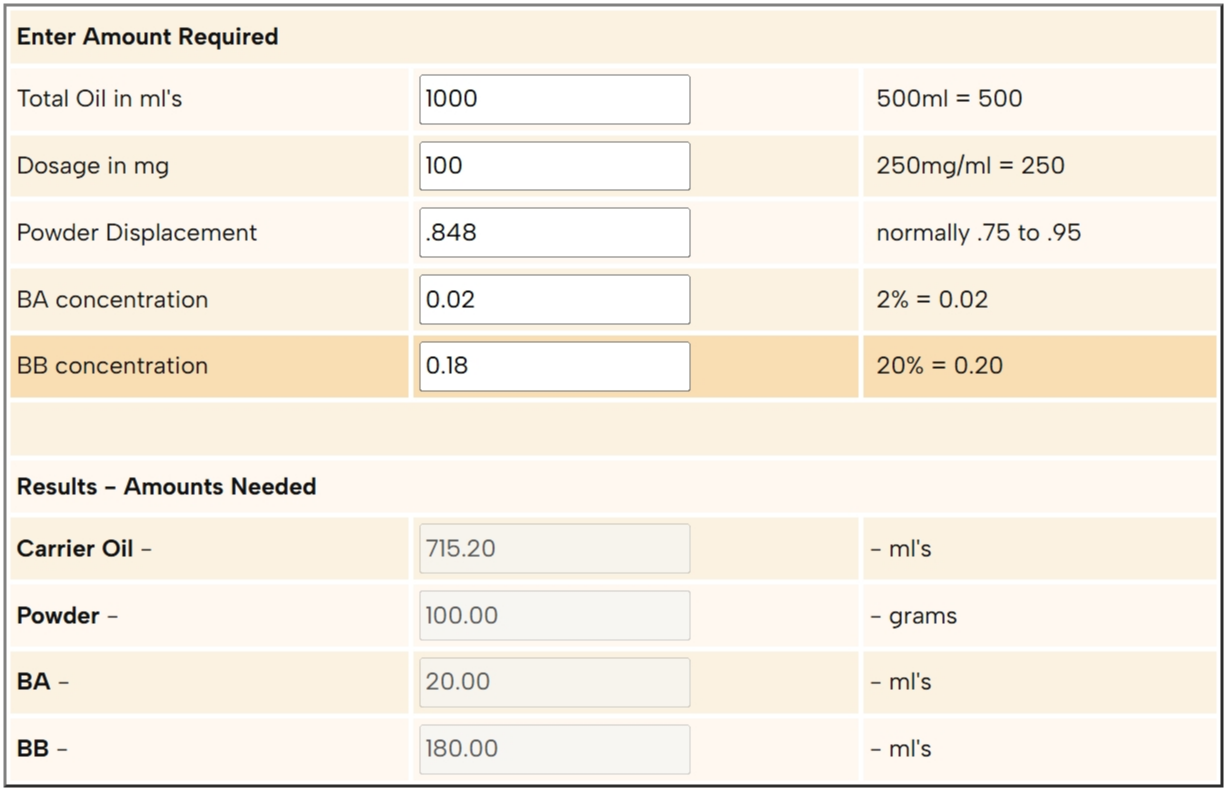

We need to calculate a little bit on the recipe which we are going to use and confirm the required amounts for each ingredients. This is a steroid powder to oil conversion calculator. For example, we have 100g tren ace powder in hand and we’re going to make it into 100mg/ml oil, then the total volume (let’s name it as V1) is:

100g × 1000 = 100,000mg

V1 = 100,000mg ÷ 100mg/ml = 1,000mL

According to the steroid powder calculator, we need:

Tren ace powder: 100g

BA: 20mL

BB: 180mL

MCT: 715.2mL

Weigh out and get all the ingredients ready for use.

Step 2. melting tren ace powder

- Get a 1000mL volume beaker and add 100g tren ace powder into the beaker.

- Add 180mL BB into the beaker.

- Heat the beaker by water bath or use a magnetic stirrer until tren ace powder melted completely, then we got tren ace conversion.

- Add 20mL BA into the conversion.

- Add 715.2mL MCT oil or any carrier oil you’re using.

- Keep heating and stirring the conversion for 20 mins at about 100~110 °C.

- Done! We have made the tren ace 100mg/ml oil.

Step 3. filtering tren ace 100 oil

To make tren ace 100mg/ml oil sterile, necessary sterile filtration with proper device is required. There are multiple types of filtration media are available in flat format or encapsulated. We choose by loading capacity. Membranes have inherently low loading capacity. For 1000mL, we could use both bottle-top filter device or capsule filter device with a peristaltic pump for fast filtering. No matter what the device is, the core functioning part is the filter membranes (or filter papers) to remove the microbe - filtering membrane with 0.22μm pore size will let the oils pass while keep the microbes.

The life of a membrane filter can be extended many times by placing a prefilter upstream of the membrane. The total particulate load challenging the membrane is considerably reduced thus allowing the membrane to operate efficiently.

- Setup your filter device and add tren ace 100mg/ml oil into the filter device.

- Carry your sterile tren ace oil 100mg/ml in a sterile container.

Step 4. filling sterile-filtered tren ace 100 oil into vials

There are also many types of filing machine to choose from. Choose it by the filling speed of your machine and your goal vials. For 1000mL, it could produce about 90 vials, 10mL per vial - considering the loss during the work flow. We can use a peristaltic pump to finish the job.

Setup your filling machine and fill the sterile oils into you sterile vials.

At the same time, plug the rubber stopper and put on the flip off caps.

Step 5. Seal your vials

For low capacity production, we can crimp the vials by manual crimper or semi-auto crimper.

For mass production, we might need to use a mini desktop automatic production line or a full production line.

Step 6. Stick the label and packaging it

Stick your product info labels with a manual label sticker machine or an automatic one. You can also put your anti-couterfeit label to the vials.

Put your vials into the paper box and they’re ready for use.

All done!